Paper Tube Crushing Machine

Paper core crusher machine is ideal equipment to crush various types of paper rolls, such as paper tube, paper core, paper tube, into powder. The max diameter OF PAPER CORE can be 40cm.

Description

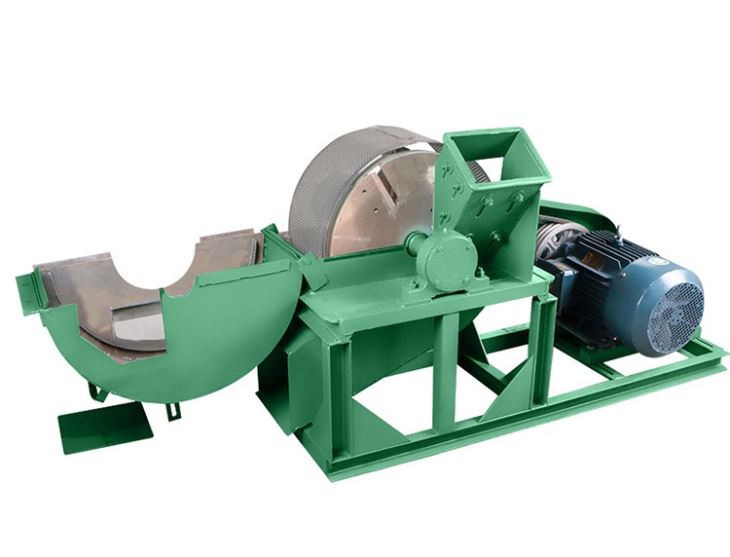

Paper Tube Crushing Machine

Instruction of paper tube crushing machine

A paper core crusher machine is an ideal equipment to crush various types of paper rolls, such as a paper tube, paper core, or paper tube, into powder. The max diameter OF the PAPER CORE can be 40cm.

How does a paper core crusher work?

The paper roll crushing machine is made up of a base frame, motor, disc rotor, blades, hammers, screen, feeding chute, and discharge chute. The disc rotor is driven by the motor directly through the V-belt, on the disc rotor there are cutting blades and fan blades, when the wood feeds from the feeding chute, it touches the rotating disc rotor, and the cutting blades on the disc rotor will cut the wood to pieces, the wood pieces go inside the crushing chamber, the high speed rotating hammers will bating the wood pieces again and again, unless the size of wood is smaller than the hole of the screen it will pass the holes of the screen and discharged from the discharge chute. The hole of the screen decides the size of sawdust made from the wood crusher. The feeding chute size decides the diameter of wood that can feed into the wood crusher.

Technical data of paper tube crushing machine

| Model | FS400 | FS500 | FS600 | FS700 | FS900 |

| Capacity | 400-600kg/h | 600-800kg/h | 800-1200kg/h | 1000-1500kg/h | 1500-2000kg/h |

| Main motor power | 7.5kw | 18.5kw | 30kw | 37kw | 55kw |

| Blades quantity | 4 | 4 | 4 | 6 | 8 |

| Blades length | 90mm | 100mm | 130mm | 150mm | 200mm |

| Max feeding wood φ | 140mm | 160mm | 180mm | 190mm | 200mm |

| Final sawdust size 3-5mm or can be customized |

Advantage of paper roll paper tube crushing machine

1. Reasonable design, improves crushing efficiency by 50% compared to the traditional type.

2.Attractive appearance, high output of 400-5000kg per hour.

3.One motor drives crushing, energy-saving, and low cost.

4.Crushed materials are used in charcoal briquette making machines and biomass pellet making machines.

Paper roller, paper tube crusher Maintenance

The bearings should be injected with oil after the machine working for three to four hours.

Adjust the tightness of the V belt after using it for a period, lower 6-10mm is suitable.

Clean and examine carefully every part of the machine, if there is any malfunction, repair in time.

Details for paper roller, paper core, paper tube crushing machine

Hot Tags: paper tube crushing machine, China, manufacturers, factory, buy, cheap, price, for sale